Wheat flour is a powder made from the milling or grinding wheat used for human consumption. Wheat flour making process main include wheat cleaning and wheat milling. During the wheat milling process, different parts of the wheat grain are used to make different types of flour. White flour is made from the endosperm only. Wholemeal flour uses all parts of the grain:the endosperm, the wheat germ and the bran layer. Brown flour contains about 85% of the original grain, but some brain and germ have been removed.

Wheat composition

Carbohydrate 70%

Protein 9-15%

Fat 2-2.2%

Fiber 2-2.5%

Ash 1.8%

Moisture 9-13%

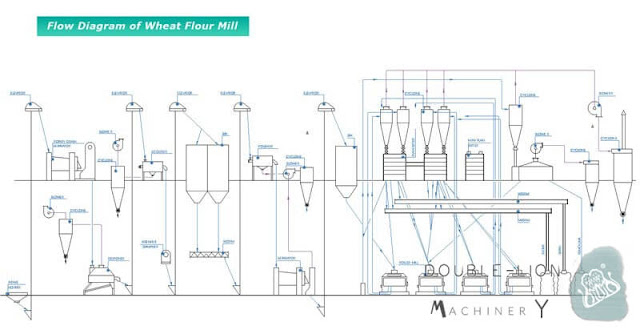

Wheat Flour Making Process

Delivery And Storage Of Wheat

Each received wheat at the flour mill factory is tested against a contract specification for variety, moisture content, specific weight, impurities, enzyme activity associated with sprouting, protein content and quality, the wheat is graded based on these factors. In passed through a preliminary cleaning process to remove coarse impurities, such as nails and stones, and may be dried before stored in silos according to quality.

Wheat Cleaning Process

When wheat is drawn from the silos prior to milling, it needs several steps that separates wheat from seeds and other grains, eliminates foreign materials such as metal, sticks, stones and straw and scours each kernel of wheat.It can takes six steps.

Magnetic Separator

The first step of wheat clean is through magnetic separator to remove iron and metal particles.

Separator

Vibrating screens remove bits of wood and straw and almost anything bigger or smaller than wheat.

Suction separator

Suction separator act as a kind of vacuum to remove dust and lighter impurities

Destoner

Using gravity, the machine is according to the different specific gravity and suspension speed between seeds and dinas, make use of the combine effect of wind-force and vibration, to separate the stone and impurities in the grains.

Cockle cylinder

Wheat passes through a separator that identifies the size of the kernels even more closely. It rejects anything longer, shorter, more round, more angular or in any way a different shape.

Wheat scourer

The wheat scourer removes outer husks, crease dirt and polish the outer surface with an intense scouring action. Currents of air pull all the loosened material away.

Conditioning And Tempering Process

Wheat is conditioned for milling. Moisture is added in certain amounts to toughen the bran and mellow the inner endosperm. This help the parts of the kernel to be separated easily and cleanly • Tempered wheat is stored in bins from 8-24 hours, depending on the type of wheat - soft, medium or hard

Blending Process

Cleaned and conditioned wheat is then blended in a process known as gristing. This combines different wheats to produce a mix capable of yielding the required of flour.

Milling or Grinding Process

Milling

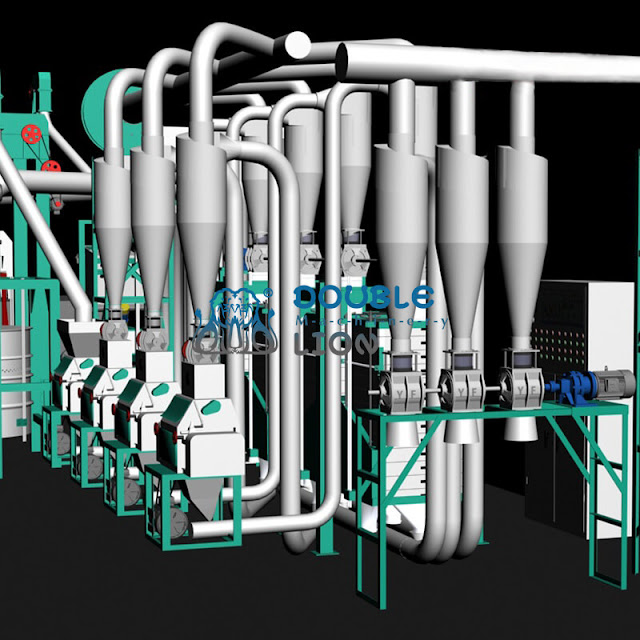

Milling process is a gradual reduction of the wheat kernels to produce particles of endosperm which are then graded and separated from the bran by sieves and purifiers. Each size returns to corresponding rollers and the same process is repeated until the desired flour is obtained. The rolls are paired and rotate inward against each other, moving at different speeds.Just one pass through the corrugated "first break" rolls begins the separation of bran, endosperm and germ. The milling machine include small flour mill machine, pneumatic flour mill machine and stone grinding mill machine, you can select it according to your need.

Sifting

The broken particles of wheat are introduced into huge, rotating, box-like sifters where they are shaken through a series of bolting cloths or screens to segregate the larger from the smaller particles. Up to 6 different sizes of particles may come from a single sifter, including some flour with each sifting. Larger particles are shaken off from the top, or "scalped," leaving the finer flour to sift to the bottom. These fractions are sent to other roll passages and particles of endosperm are graded by size and carried to separate purifiers

Purifier

In a purifier, a controlled flow of air lifts off bran particles while at the same time a bolting cloth separates and grades coarser fractions by size and quality

In a purifier, a controlled flow of air lifts off bran particles while at the same time a bolting cloth separates and grades coarser fractions by size and quality

Packing Process

Wheat flour packing process is the last step of flour making. DCS series quantitative automatic packing scale contains two forms of double screw conveyor and single screw conveyor. Double screw conveyor is suitable for precise measuring and packing of large and medium yield package, while single screw conveyor is suitable for small and medium automatic flour presser factory.

Wheat flour packing process is the last step of flour making. DCS series quantitative automatic packing scale contains two forms of double screw conveyor and single screw conveyor. Double screw conveyor is suitable for precise measuring and packing of large and medium yield package, while single screw conveyor is suitable for small and medium automatic flour presser factory.

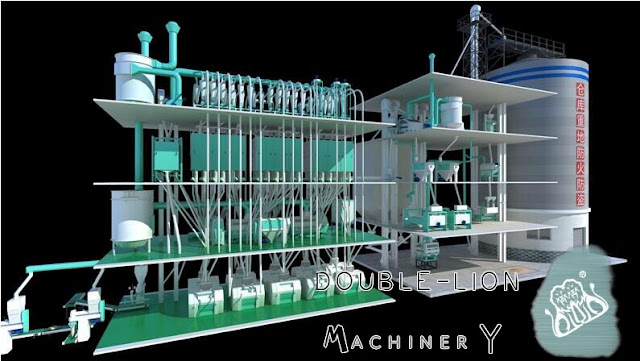

Today, make wheat flour is a very simple thing. The technology of flour milling has developed very well. Different automatic wheat flour milling plant satisfy all your needs. Welcome contact Zhengzhou Double-lion Grain & Oil Machinery Co., Ltd. for more details about how to make wheat flour and how to start a flour mill business. Zhengzhou Double-lion Grain and Oil Machinery Co.,ltd have installed thousands of wheat flour mill plants and we welcome your visit to our factory and running cases at any time. We can provide flour mill process flow chart and help you flour mill plant layout design at free of charge.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: ada@zzdoublelion.com

Wechat: +8618937672012 (Ada)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.