The chickpea or chick pea has different types are variously known as gram, or Bengal gram, garbanzo or garbanzo bean, as well as the Egyptian pea. So chickpea flour which is made from dried chickpeas (garbanzo beans) also know as garbanzo flour, gram flour, and besan. Chickpeas are popular in many countries, such as India, Australia, Pakistan, Turkey and so on. Chickpeas are rich in iron, folate, phosphorus, protein and dietary fiber. Chickpeas are low in fat and most of this is polyunsaturated. Scientists researched that chickpea consumption may lower blood cholesterol. Therefore, chickpeas and chickpea products have become one of the healthy food in our diet. And it goes without saying that chickpeas processing equipment will also become more and more popular.

Last spring, one Pakistan customer contact with us for the chickpea flour mill machine. He needs the chickpea flour milling machinery very urgently. We discussed a lot about his requirements, like the fineness of the final flour, the use of the chickpea flour, the packing, and some more detailed information. Based on the requirements of our client, our technician team did a special design, a technical flow sheet, a detailed list with all specifications for the chickpea flour milling machinery, that is more proper and it all meet the requirements of our client. After one month, the customer visit our factory and discussed the details further, and finally reached an agreement.

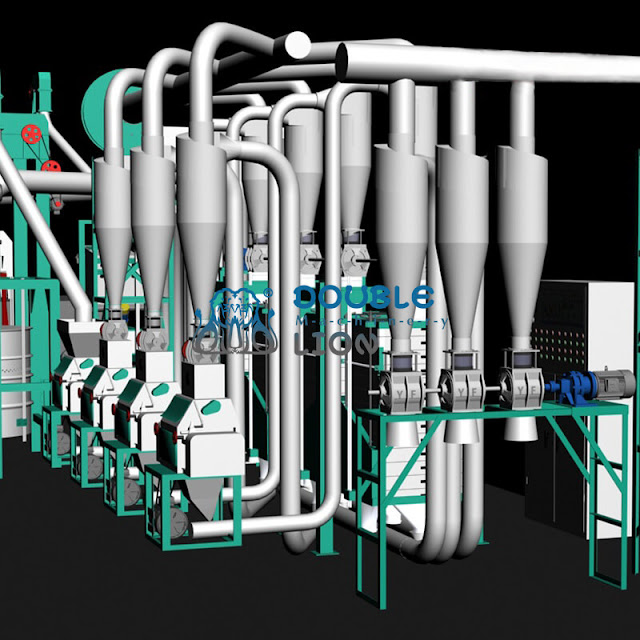

Chickpea Flour Processing Plant Usually Includes The Following Processing Steps:

1.Chickpea Cleaning System: this system includes screening sections, destoning sections and magnetic separation section to remove the big, small and light impurities, pebbles and magnetic material from the beans to ensure the quality of the end products.

2.Chickpea Color Sorting System:this system uses the color sorter to separate the moldy kernels, shriveled beans and foreign species of beans according to the color and luster feature of the beans.

3.Chickpea Peeling System:in this system uses the peeling, brushing and shunting technology (it can utilize the segregation valve to choose peeling and brushing according to the material character.)

(1)Peeling:it cal peel the bean bran and separate and collect it by effective aspiration system;

(2)Brushing: it can separate the micro bran and dust which adheres to the material surface.

4.Grading System:this is system adopts different screens and classify the material into different grades according to the size.

5.Chickpea Kernel Making and Grits Milling System:this system adopts the technology of peeling section, grits making section, grading and suspension.

(1)Peeling Section:in this section can peel the chickpea bran and separate and collect it by effective aspiration system and product whole peeled kernels;

(2)Grits Making Section:it uses fine bean grits machine and mill beans into bean grits;

(3)Bean Kernels and Bean Grits Grading Section:it adopts different screen and classifies bean kernels or bean grits into different grades according to the size.

(4)Suspension:it separates bean bran by utilizing airflow according to different material gravity.

6.Chickpea Flour Milling System:In this system, it adopts the technology of burdening, several processes of grinding and screening and grading.

(1)Burdening: it can mix different material according to different requirements for different products;

(2)Grinding: it can grind or mill the beans into fine bean flour by the professional bean grinder;

(3)Screening: it separates the chickpea flour.

Chickpea flour and grits enhance the nutrition and texture of products. Available in a variety of granulations, chickpea flour and grits have multiple uses, including extending the freshness and shelf-life of many foods.

7. Measuring and Packaging System: storage can reduce the amount of labor used. Measuring can be artificial or electronic.

Main Equipments and Functions

1. Vibrating sifter: particle materials cleaning and grading.

2. Bean peeling machine: chickpea peeling.

4. Bean brushing machine: dust, broken pericarp and mud cleaning

5. Bean milling: chickpea flour milling

6. Electrical measuring and packaging machine

If you also want to set up wheat flour mill plants, chickpea flour mill plant, maize/corn flour mill plant, welcome contact me. We supply workshop and plant drawings according to your requirement, all the machines and plants price are competitive and affordable. Welcome your inquiry and tell us your need.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.

没有评论:

发表评论