The way of stone milling to get flour is nothing new, it is the way flour was made for thousands of years before electricity came onto the scene, but lately, it’s having something of a renaissance. In addition to historic stone mills still functioning around the country, some of them still run by water power. Today new mills are popping up and artisan bakeries are even installing their own mills so they can grind flour on the premises. Today, With the emergence of electricity and the development of stone milling technology, stone milling flour processing technology is more advanced.

Stone-ground flours are thought to be more nutritionally sound because they contain the germ and bran. Incidentally, they are the parts that hold a lot of flavor, too. In fact, stone-ground flours can taste too strong for some eaters, as most people are used to baked goods where the flour stands in the background.

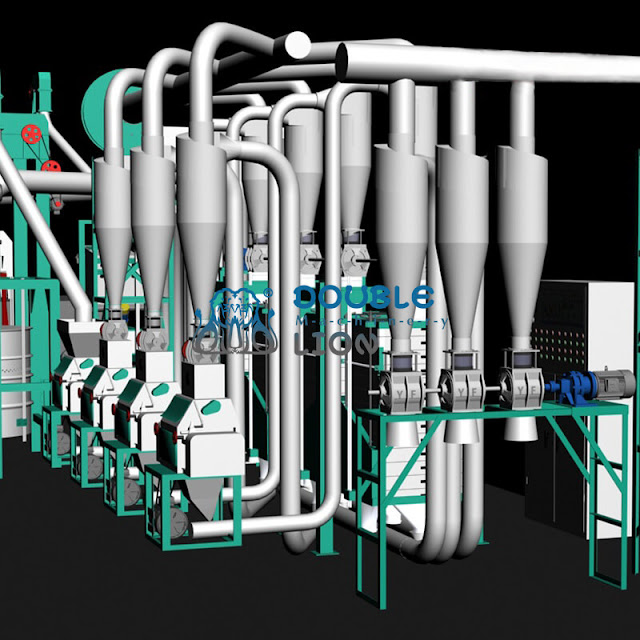

Main Advantages Of Electric Stone Flour Mill

First, compared with the mechanical flour mill, the electric stone grinding machine has the characteristics of slow grinding speed (25RPM) and low grinding temperature (normal atmospheric temperature), so that the starch in the flour will not be gelatinized due to high temperature, the nature of the protein gluten is not changed, the trace elements are not destroyed, and the processing is performed, so the favor of flour is original.

Second, the working principle of electric stone flour mill is as well as traditional stone flour mill, the flour contains mineral elements through the grinding stone milling. And it also reserve the traditional stone flour mill merits such as low speed, low speed grinding and low temperature processing, these characteristics guarantee the vitamin and trace element not damaged by high temperature, rich nutrition in flour.

Third, On the basis of traditional stone mills, functions such as automatic feeding, automatic raw material cleaning, automatic product classification, automatic packaging, etc. are added to realize fully automated production, so that the operation becomes very simple, and one to two people can complete all operations , which greatly saves manpower. Besides, it can also be used to grind the beans, grain, etc..

Four, grinding roller of electric stone flour mill is made of stainless steel, it is clean, healthful, flour feeding and discharge are convenient, especially suitable for small and large flour mill factory to produce high quality flour.

Five, the millstone is made of pure natural sandstone as raw material. The texture is hard and tough. It is rich in trace elements such as calcium, iron, zinc, selenium, etc. It does not drop slag and no pollution.

Zhengzhou Double-lion Grain & Oil Milling Machinery Co.,ltd. is professional in flour mills and flour mill plant, stone flour mill design & manufacturing. Our company long-term provides all kinds of flour processing equipment, and can also design according to customer requirements. Many foreign friends have established long-term cooperative relationship with us. Our company has wide milling machines range and competitive price, looking for sales agents overseas!

We can provide flowchart and help you design workshop at free of charge.

Need guidance to build a flour mill plant? Please contact us, our engineer will give you professional guidance and suggestion.

Type: wheat flour mill machine, flour mill, flour mill plant, stone flour mill, corn flour mill machine, grain mill, maize machine.

Get In Touch With Us

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.