Wheat flour is a powder made from the grinding of wheat used for human consumption. Wheat varieties are called “soft” or “weak” if gluten content is low, and are called “hard” or “strong” if they have high gluten content. With the development of the times, people's demand for wheat flour is increasing, and the requirements for flour types and flour quality are also increasing.

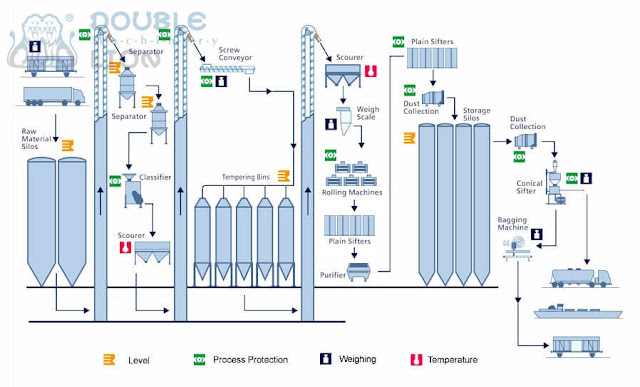

Wheat cleaning is the first step in wheat milling and is also a crucial process to ensure the quality of flour. Wheat cleaning is the use of a variety of cleaning equipment to clean up various impurities in raw wheat, so as to achieve the requirements of wheat milling. Zhengzhou Double-lion Grain & Oil Machinery Co., Ltd is the China leading manufacture of grain processing machine and grain milling plant, we also can provide flowchart and help you design workshop at free of charge. Grain cleaning machine include drum sieve pre-cleaning machine, high-frequency vibration cleaning sieve, planar rotary sifter, ZQS combined grain cleaning machine, TQLS screening and grain cleaning machine, wheat cleaning & drying machine, gravity destoner, wheat scourer, permanent magnetic drum, etc..

Drum Sieve Pre-Cleaning

This is machine is widely used in the grain cleaning process to remove impurities in grain such as wheat straw, hemp rope, paper, clod, corn cob and other similar wastes in order to avoid engine failures. It will reduce the impurities in raw materials and increase the efficiency of next cleaning process. It is mainly used in the pre-cleaning of wheat cleaning process.

This machine is mainly used for cleaning of all kinds of grain, oil and other food. It together with the aspiration channel or recycling aspiration system is widely applied in flour mills and silos storage cleaning section. It also successfully used in feed mills, seeds cleaning plants, oil seed cleaning plants, cocoa bean and coca nibs grading systems in chocolate factories and other plants.

This equipment is used primarily for grain cleaning in the flour milling plant, such as wheat, durum, corn, rye, soybeans, buckwheat, spelt, millet and rice. By replacing the sieve plates with different apertures, the impurities in the granular materials can be cleaned. Combined with wind, this rotary sifter cleaning sieve runs with several tracks at the same time. It is mainly used to clean big, small and light impurities is granular stuff. The size of sieve pore can be adjusted according to the size and shape of raw material,and by adjusting rotary speed and weight of balance block, its amplitude is changed so as to achieve the optimum cleaning effect.

ZQS Combined Grain Cleaning Machine

This equipment combine the function of grinding, sieving, de-stoning, automatic watering and air conveying, it must work with a low pressure air blower and necessary air blower and necessary air pipes. It adopts technique of using screening, stoning and thrashing in the whole process.

This equipment combine the function of grinding, sieving, de-stoning, automatic watering and air conveying, it must work with a low pressure air blower and necessary air blower and necessary air pipes. It adopts technique of using screening, stoning and thrashing in the whole process.

This is high frequency screening and stone cleaning machine, mainly used for wheat cleaning. It has the functions of screening, stone-removing, and scouring, the machine is ideal equipment to food processing plants.

Wheat Cleaning & Drying Machine

This series wheat cleaning & drying machine is a kind of wheat cleaning equipment which is used to separate the impurities and mud from wheat in flour cleaning process. By cleaning wheat, it can clean soil, pesticide, microorganism, eggs, and pollutants on the surface or in the ventral canal, and increase moisture to improve the physical properties of wheat and grinding effect.

This series wheat cleaning & drying machine is a kind of wheat cleaning equipment which is used to separate the impurities and mud from wheat in flour cleaning process. By cleaning wheat, it can clean soil, pesticide, microorganism, eggs, and pollutants on the surface or in the ventral canal, and increase moisture to improve the physical properties of wheat and grinding effect.

Wheat Destoner

This specific gravity destoner manufactured by Zhengzhou Double-lion is widely used in the flour milling, rice milling, feed and food processing industries home and abroad, which is according to the different specific gravity and suspension speed between seeds and dinas, make use of the combine effect of wind-force and vibration, to separate the stone and impurities in the grains. The machine has a grade to gravel, good performance of mud removing, low power consumption, no dust outside, low noise, easy operation and maintenance and is mainly used for grading and removing stone of wheat, rice, peanuts, corn, soybeans, and other grains.

This specific gravity destoner manufactured by Zhengzhou Double-lion is widely used in the flour milling, rice milling, feed and food processing industries home and abroad, which is according to the different specific gravity and suspension speed between seeds and dinas, make use of the combine effect of wind-force and vibration, to separate the stone and impurities in the grains. The machine has a grade to gravel, good performance of mud removing, low power consumption, no dust outside, low noise, easy operation and maintenance and is mainly used for grading and removing stone of wheat, rice, peanuts, corn, soybeans, and other grains.

The more information about the grain cleaning machine and flour mill machine, flour mill plants from 5TPD to 500TPD, please contact us:

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.