Flour milling business is one of the most traditional businesses all over the world. Flour is such a useful ingredient to make various types of processed foods like biscuits, bread, noodles, pasta and fast foods like pizza, burger, doughnuts etc. Due to health benefits of chakki-fresh flour these days, we have shifted towards it and naturally the demand of flour mills has started growing . As more and more people are becoming health conscious, the flour milling business will be profitable and never show a downward trend.

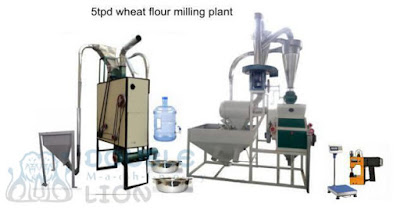

If you are starting a flour processing business for the first time, you can start from a small scale, such as 5TPD flour mill plant, 10TPD flour mill plant and 20TPD flour mill plant. Model of DLWF5 flour mill plant developed by Zhengzhou Double-lion is a new type of small flour milling project, which is very suitable for the new flour processing industry.

DLWF5 Flour Mill Plant (Capacity is 5TPD) using the whole wind transport air delivery automatic feeding system, mainly composed by the two parts of grain cleaning machine and flour mill. This flour mill plant has the features of compact structure, specification design, beautiful appearance, high degree of automation, reliable performance, stable operation, low noise and convenient operation. The equipment adopts the selected grinding roller tooth and tooth angle, the convenient material distribution structure of the hopper, the reasonable grinding technology, the processed flour is fine, white and rich in flavour. We have exported this small flour mill plant to India, America, Belgium and many other countries. If you are ready to start a 5TPD flour mill plant, here are simple steps you need.

If you are starting a flour processing business for the first time, you can start from a small scale, such as 5TPD flour mill plant, 10TPD flour mill plant and 20TPD flour mill plant. Model of DLWF5 flour mill plant developed by Zhengzhou Double-lion is a new type of small flour milling project, which is very suitable for the new flour processing industry.

DLWF5 Flour Mill Plant (Capacity is 5TPD) using the whole wind transport air delivery automatic feeding system, mainly composed by the two parts of grain cleaning machine and flour mill. This flour mill plant has the features of compact structure, specification design, beautiful appearance, high degree of automation, reliable performance, stable operation, low noise and convenient operation. The equipment adopts the selected grinding roller tooth and tooth angle, the convenient material distribution structure of the hopper, the reasonable grinding technology, the processed flour is fine, white and rich in flavour. We have exported this small flour mill plant to India, America, Belgium and many other countries. If you are ready to start a 5TPD flour mill plant, here are simple steps you need.

1.Main Equipment

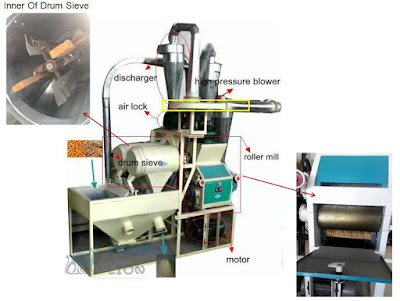

Grain Cleaning Machine:combined grain cleaning machine, wheat washer & dryer

Grain Milling Machine:automatic flour mill, grain brusher

Packing Machine:electronic scale, hemming machine

Other auxiliary equipment and accessories

2.Workshop and Power

Workshop size:4×6×3.5m

Power:18.5kw

3.Location Selection

The location of the milling business is among the things you cannot ignore when entering this field. The location will determine the success of your business. The business should be situated such that it can conform to the zoning regulations of the region. If you are going to ignore this, there are high chances that your business will not perform well at the end of the day. Therefore, it is wise to conduct market research so that you can determine some of the best places where you can establish the business in question. If you are not sure about the location, it is advisable to consult a few experts over the same. It does not make sense to pump a lot of money in a business located at the wrong place. There are high chances that you will end up failing and closing down the doors of your small company.

4.Investment Needs of the Small Scale Flour Milling Business

It is not possible to run a milling business without capital. It is recommended to perform an analysis of the amount of money and other resources you will require in order to start and maintain your business. There are different ways to finance the business including loans and personal cash. You need roller mills, sifters as well as aspirators among other equipment to start the operations of your business. In addition, you will need facilities that will help you when it comes to drying as well as storage of the products. Therefore, make sure that you have adequate amount of money to perform this.

5. Flour Milling Process

(1)Pouring the wheat to the first wheat tank

(2)Fill water to the dampener

(3)Then get the clear wheat, tempered for half an hour, let the wheat get enough water.

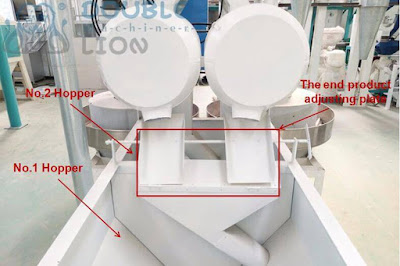

(4)Lifting wheat: pouring the clean wheat to the No.1 hopper, (there are some tips here), under the No.1 and No.2 hopper, there is an adjusting plate, that can decide which hopper flow wheat to the mill. There is also an adjusting handle, as usual, No.1 hopper for the raw wheat, after raw wheat be milled once, the not good flour will be lift to the No.2 hopper, with the help of the end product adjusting plate, then mill twice, then the not good flour be poured No.1 hopper, thus to achieve times by times milling, finally get the wanted flour.

Workshop size:4×6×3.5m

Power:18.5kw

3.Location Selection

The location of the milling business is among the things you cannot ignore when entering this field. The location will determine the success of your business. The business should be situated such that it can conform to the zoning regulations of the region. If you are going to ignore this, there are high chances that your business will not perform well at the end of the day. Therefore, it is wise to conduct market research so that you can determine some of the best places where you can establish the business in question. If you are not sure about the location, it is advisable to consult a few experts over the same. It does not make sense to pump a lot of money in a business located at the wrong place. There are high chances that you will end up failing and closing down the doors of your small company.

4.Investment Needs of the Small Scale Flour Milling Business

It is not possible to run a milling business without capital. It is recommended to perform an analysis of the amount of money and other resources you will require in order to start and maintain your business. There are different ways to finance the business including loans and personal cash. You need roller mills, sifters as well as aspirators among other equipment to start the operations of your business. In addition, you will need facilities that will help you when it comes to drying as well as storage of the products. Therefore, make sure that you have adequate amount of money to perform this.

5. Flour Milling Process

(1)Pouring the wheat to the first wheat tank

(2)Fill water to the dampener

(3)Then get the clear wheat, tempered for half an hour, let the wheat get enough water.

(4)Lifting wheat: pouring the clean wheat to the No.1 hopper, (there are some tips here), under the No.1 and No.2 hopper, there is an adjusting plate, that can decide which hopper flow wheat to the mill. There is also an adjusting handle, as usual, No.1 hopper for the raw wheat, after raw wheat be milled once, the not good flour will be lift to the No.2 hopper, with the help of the end product adjusting plate, then mill twice, then the not good flour be poured No.1 hopper, thus to achieve times by times milling, finally get the wanted flour.

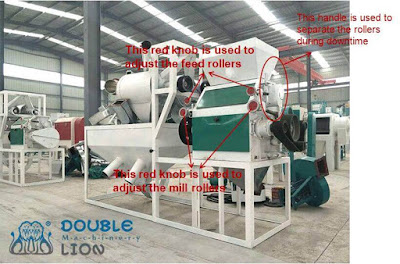

(5)The Adjustment Of The Roller Distance

There are two knobs on the right, the upper right knob is controls the outside roller-faster roller. The right knob down is controlling the inside roller-slow roller. The distance between the roller, also affect the fineness of flour. Firstly, relative wide distance, then narrow, more marrow.

Zhengzhou Double-lion supply workshop and plant drawings according to your requirement at free charge, all the machines and plants price are competitive and affordable. Welcome your inquiry and tell us your need.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.

没有评论:

发表评论