What Is Wheat Flour Mill Plant?

The wheat flour mill plant is a process industry to mill grains into maida, sooji, and atta. The skin or bran is separated from the endosperm and sold as cattle feed. Wheat flour milling business is one of the most traditional business all over the world. Today, to start a flour mill plant is an so easy, you can start this business in both city and rural areas.Since wheat flour is a staple food among all segments of the population, it can be used to make various types of processed foods, such as biscuits, bread, noodles, pasta and fast foods like pizza, burger, doughnuts, etc. Additionally, these are the items for domestic daily use. Furthermore, the bakery industry hugely depends on these ingredients as raw materials. So there is a constant demand in the consumer market for wheat products and the demand for these is always on the increase. The flour mill plant is a financially profitable business.

Most Profitable Of Flour Mill Business

Gram Flour: The most common name of the gram flour is besan. And the product has a great demand in our country.

Sooji: Sooji is an another very popular grocery item in our country. You can produce sooji from the same manufacturing unit.

Wheat Flour (Atta): Atta is one of the most essential items for the domestic kitchen.

Wheat Flour (Maida): Maida has comparatively more demand than atta.

Maida, Sooji, and Atta are packed in 50kg bags. For the retail commercial market, 500 grams and 1-kilogram packaging are adopted.

Wheat Flour Mill Plant Production Capacity

Zhengzhou Double-Lion Grain Oil Machinery Co.,Ltd has rich experience in designing and manufacturing wheat flour mill machine and wheat flour mill plants with capacity from 10T to 500 T per day(24 working hours)

The recovery of finished products will be equivalent to the raw material input.

The output of various fractions is termed as extraction percentages. A typical extraction comprises 60% refined flour or maida; 10% semolina or sooji; 7% resultant meal or atta and 13% bran.

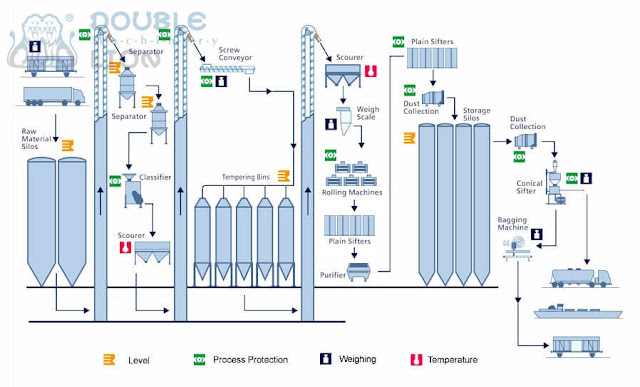

Whole Wheat Flour Plant Production Process

The milling of wheat is basically divided into two sections viz:- cleaning section and the milling section. The milling section comprises the chaff remover; destoner; scourer; washing machine; intensive dampener; and cockle separator. In the cleaning section, wheat is cleaned thoroughly before milling. Wheat is first passed through sieves to remove chaff and stalks. From the chaff separator, it passes through a scouring machine wherein adhering dirt and mud and a part of the skin are removed. From the scourer, the wheat passes through the destoner and stones are completely separated from the grain. The grains are then fed into the washing machine where dust, husk and mud balls are removed. The washed wheat is sent through a dampened to raise the moisture content of the grain and then for conditioning. After conditioning for 36 hours, it is drawn for milling. The grain passes through a series of milling rolls comprising the break rolls, scratch rolls, and the polish rolls, purifiers, and plan sifters to get the desired fractions at the required percentages.

The different product shall conform to the following specifications:

• Atta:- Moisture -13.5% maximum; Ash - 2% maximum; Acid insoluble ash - 0.18% maximum; Gluten - 6% minimum; Alcoholic acidity - 0.18% maximum; Rodent excreta and human hair - absent.

• Maida:- Moisture -13.5% maximum; Ash - 1% maximum; Acid insoluble ash - 0.10% maximum; Gluten - 7.5% minimum; Alcoholic acidity - 0.12% maximum; Rodent excreta and human hair - absent.

• Sooji:- Moisture -13.5% maximum; Ash - 1% maximum; Acid insoluble ash - 0.15% maximum; Gluten - 6.0% minimum; Alcoholic acidity - 0.18% maximum; Rodent excreta and human hair - absent.

Machinery and Equipment Costing

Preparatory section

a) Chaff separator

b) Scourer

c) Destoner

d) Washing machine

e) Intensive dampeners

f) Elevators and conveyors

g) Motors for above machines

Process section

h) Roller machine

i) Purifiers

j) Plansifter

k) Pneumatic elevation system with pipings

l) Bran finisher

m) Motor and accessories

n) Tool kit, weighing scales and accessories.

Testing equipment

The Total Plant Costs can be from 20,000 USD to 450,000 USD.

We supply workshop and plant drawings according to your requirement, all the machines and plants price are competitive and affordable. Welcome your inquiry and tell us your need.

Need guidance to build a maize flour plant? We Are a Professional Manufacturer of Maize and Wheat Flour Mill. Timely After-sale Service · Professional Supplier · Exported to 120 Countries · 2%-10% Discount

Types: corn flour mill machine, grain mill, maize machine, wheat flour mill machine, flour mill plants. Get in touch with us.

How to Get in Touch with Zhengzhou Double lion Flour Mill Manufacturer

Email: info@zzdoublelion.com

Whatsapp: +8613849022317 (Sophia)

Wechat: +8613849022317 (Sophia)

Add:Lotus street NO.100,Hi-tech development zone, Zhengzhou, Henan, China.

没有评论:

发表评论